Thermoforming Machines for High Volume Packaging Production

Thermoforming Machines for High Volume Packaging Production are a crucial part of large-scale manufacturing lines. Thermoforming machines mold plastic sheets into various shapes by heating them until they become pliable and then forming them into the desired shape using molds. These machines offer an efficient and cost-effective way to produce packaging products in large quantities. Whether it’s for food packaging, medical device packaging, or consumer goods, thermoforming is widely used in high-volume applications due to its speed, flexibility, and ability to produce precise results.

Table of Contents

In the world of high-volume packaging, thermoforming plays a vital role in ensuring that products are not only produced quickly but also meet the necessary standards of quality. With thermoforming, manufacturers can produce large batches of products with minimal waste and a high degree of accuracy. This is crucial in industries that require large quantities of packaging items to be produced within tight time frames. Thermoforming machines can be tailored to accommodate different types of materials, making them versatile for various packaging needs.

The efficiency of Thermoforming machines in high-volume production is driven by their automation and precision. These machines can work continuously at a high rate, producing large quantities of packaging without compromising quality. In addition to the speed, the ability to produce intricate and detailed designs means that thermoforming machines are indispensable for industries where packaging needs to be both functional and aesthetically pleasing. As such, thermoforming technology remains a top choice for manufacturers who require high-volume production capabilities.

What is High-Volume Production?

High volume production refers to the manufacturing process that involves the creation of large quantities of products in a short period of time. It is common in industries where demand for products is consistently high, such as food and beverage packaging, medical device packaging, and consumer goods packaging. In high-volume production, manufacturers focus on producing products efficiently while maintaining consistent quality, minimizing downtime, and optimizing resource use.

This type of production typically involves automated systems and machinery that can handle high-output demands. The goal is to produce a large number of items in a streamlined manner without sacrificing the precision or quality required. High-volume production is characterized by the use of specialized machinery designed to meet the demands of speed, capacity, and flexibility. It is a critical component of industries where large-scale manufacturing is required to meet consumer or market needs.

In high-volume production, efficiency and cost-effectiveness are key considerations. Manufacturers aim to produce as many units as possible while minimizing waste, labor costs, and energy consumption. Technologies like thermoforming machines play a significant role in achieving these goals, allowing companies to meet the high demand for packaging products without compromising on quality or delivery times.

Why Should You Choose High-Volume Production?

Choosing high-volume production offers several benefits to manufacturers, particularly in industries with high product demand. One of the primary reasons to opt for high-volume production is the cost savings. By producing in large quantities, manufacturers can lower the per-unit cost of production, making it more economical. This is especially important in competitive markets where pricing plays a significant role in attracting customers and staying ahead of competitors.

High-volume production also helps meet the fast-paced demands of the market. With the ability to produce a large number of units quickly, companies can ensure that they are always stocked and ready to ship. This reduces the risk of stockouts and the potential for lost sales, which can occur if production cannot keep up with demand. Additionally, high-volume production enables companies to quickly adapt to changes in consumer preferences or seasonal spikes in demand, ensuring they remain agile in a competitive marketplace.

Another benefit of high-volume production is the improved consistency and reliability it offers. When production processes are standardized and automated, it becomes easier to maintain consistent quality across all units produced. This is particularly important in industries where product uniformity is essential, such as food packaging or medical device manufacturing. With high-volume production, manufacturers can ensure that each product meets the same high-quality standards, reducing the chances of defects and improving customer satisfaction.

Efficiency Improvement for High-Volume Production with Thermoforming Machines

Thermoforming machines are a game-changer for manufacturers looking to improve efficiency in high-volume production. These machines are designed to automate the thermoforming process, allowing for rapid heating, molding, and cooling of plastic sheets to create packaging products. By automating these processes, thermoforming machines reduce the amount of manual labor required, which leads to faster production times and fewer human errors.

Thermoforming machines also contribute to efficiency by minimizing waste. Traditional manufacturing methods often result in a significant amount of scrap material, which can be costly for companies. However, thermoforming machines are designed to optimize material usage by accurately heating and forming plastic sheets. This reduces waste, saves on material costs, and makes the production process more environmentally friendly.

Moreover, the flexibility of thermoforming machines allows manufacturers to quickly switch between different designs and product specifications. This makes it easier to respond to changing market demands without requiring extensive retooling or downtime. The adaptability of thermoforming machines ensures that production schedules remain on track, even when production runs need to be adjusted to accommodate new designs or specifications. This level of flexibility and speed is crucial for maintaining high levels of efficiency in high-volume production.

Why Should Thermoforming Machines Be Preferred for High-Volume Packaging Production?

Thermoforming machines are an ideal choice for high-volume packaging production due to their ability to offer both speed and precision. Unlike other methods of packaging production, thermoforming allows manufacturers to produce large quantities of products in a short period of time while maintaining consistent quality. This is essential in industries like food packaging or pharmaceuticals, where packaging needs to be both fast and reliable.

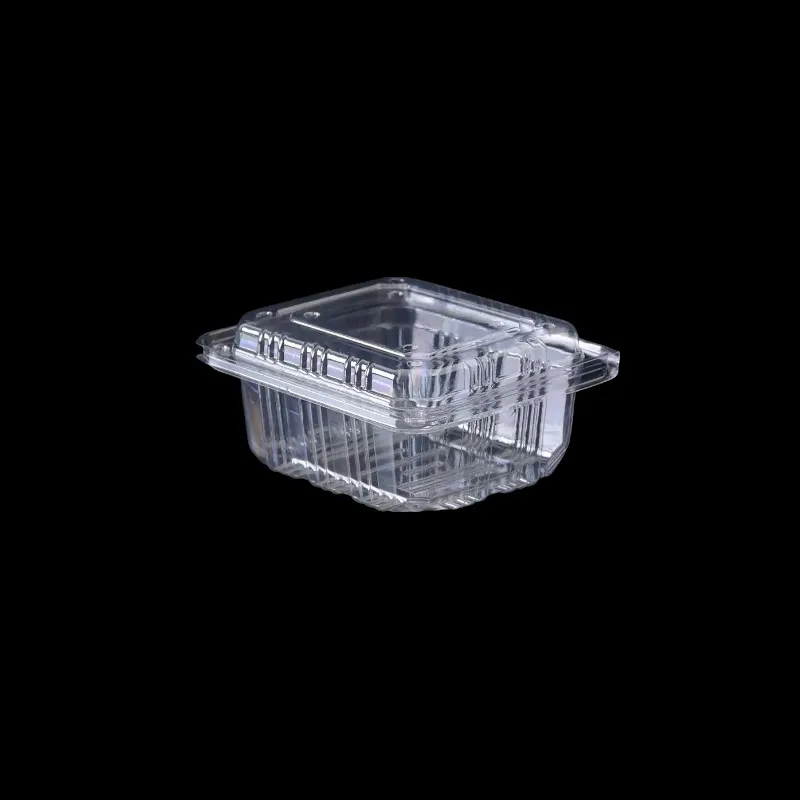

Another key advantage of thermoforming machines is their versatility. These machines can work with a variety of plastic materials, including polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), and many others. This makes thermoforming a highly adaptable solution for producing a wide range of packaging types, from clamshells and blister packs to trays and custom containers. The ability to use different materials for different applications further enhances the flexibility of thermoforming machines.

Additionally, thermoforming machines are designed to minimize downtime and maintenance. With their robust construction and automated features, these machines can operate continuously for long periods of time without requiring frequent interventions. This reduces the cost of labor and maintenance, which is a significant factor when considering the total cost of ownership. For companies that need to maintain high production rates, thermoforming machines offer an excellent solution to meet the demands of high-volume packaging production.

High-Performance Thermoforming Machines for Fast Production from INPAK

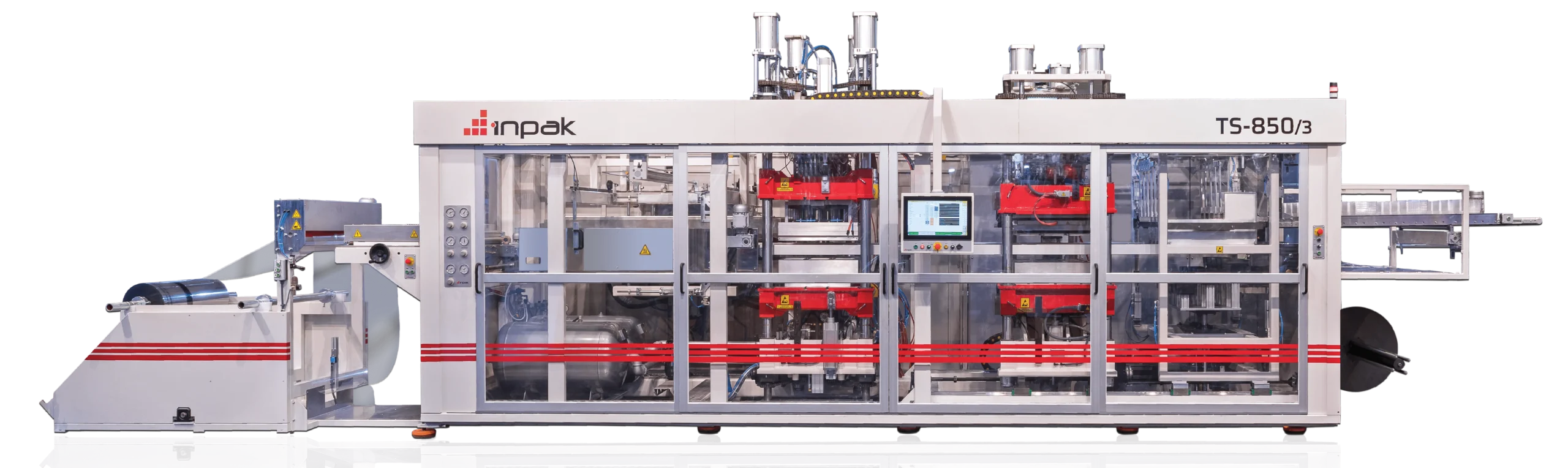

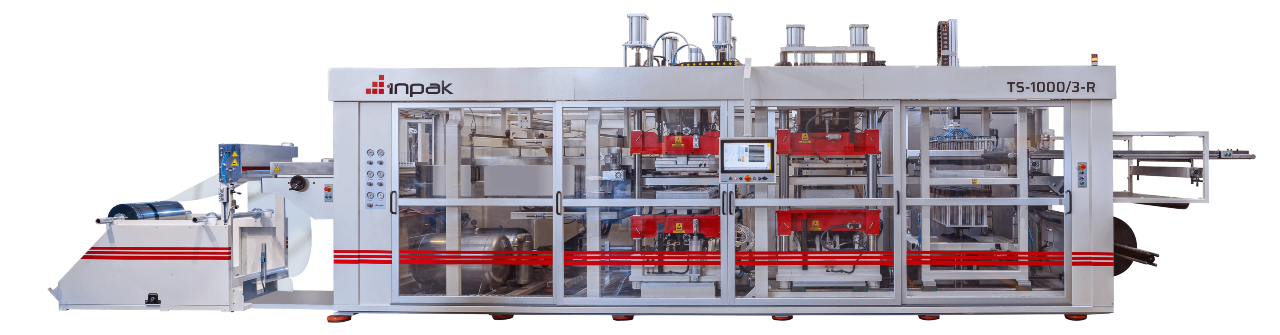

INPAK is a leading provider of high-performance thermoforming machines that cater to the needs of high-volume packaging production. These machines are designed to maximize production speeds while ensuring the highest levels of precision and quality. With advanced features such as automatic sheet feeding, precise temperature control, and high-speed molding capabilities, INPAK’s thermoforming machines are built to handle the demanding requirements of fast-paced production environments.

One of the standout features of INPAK thermoforming machines is their energy efficiency. These machines are engineered to consume less energy while maintaining high output levels, which helps companies reduce their overall production costs. This is particularly important in high-volume production, where energy consumption can quickly add up. By using innovative technologies, INPAK’s thermoforming machines offer an environmentally friendly solution for packaging production.

INPAK also offers customized solutions to meet the specific needs of different industries. Whether it’s packaging for food, medical devices, or consumer goods, INPAK’s thermoforming machines can be tailored to accommodate a wide range of materials, shapes, and sizes. This flexibility allows manufacturers to optimize their production processes and stay ahead of the competition by offering a diverse range of high-quality packaging products.