Separator – Material Handling Trays – Thermoforming Machine

Thermoform separator machines play a crucial role in the plastic packaging industry, ensuring precise separation of formed plastic components. These machines enhance efficiency in thermoforming production lines by automating the cutting and separation process. By integrating a well-designed thermoform separator machine, manufacturers can achieve higher precision, reduce material wastage, and improve overall productivity.

Table of Contents

The manufacturing and installation of thermoform separator machines require specialized engineering and high-quality components to meet the stringent demands of the industry. Companies that manufacture thermoforming machines, such as Inpak, focus on delivering advanced solutions tailored to customer needs. A well-optimized thermoform separator machine ensures that plastic packaging production is seamless, cost-effective, and environmentally sustainable.

As the demand for high-quality plastic packaging grows, businesses must invest in efficient thermoforming technologies. A reliable thermoforming machine manufacturer like Inpak provides cutting-edge separator machines designed to enhance the efficiency of production lines. These machines contribute significantly to the overall success of packaging manufacturers by offering superior speed, accuracy, and reliability.

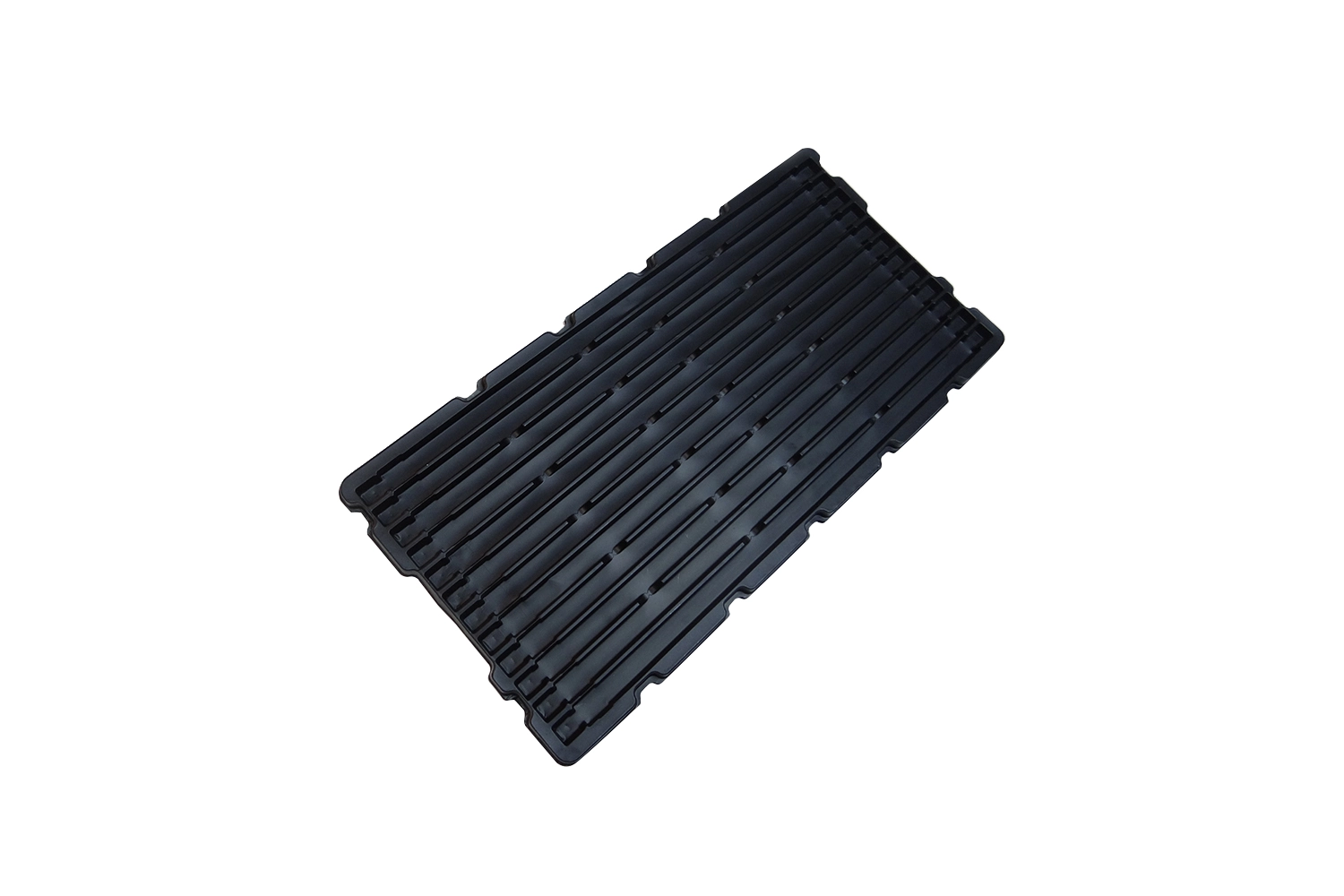

Separator Trays in Thermoforming

Separator trays are essential components in the packaging and logistics industries. These trays are designed to organize products and keep them separated during storage or transportation. Made from durable, lightweight plastic, thermoformed separator trays are crafted to fit specific needs, whether it’s for food, electronics, or automotive parts. The thermoforming process allows these trays to be molded with intricate designs, making them perfect for organizing items while preventing damage.

Thermoforming involves heating a plastic sheet to a pliable state, which is then formed into specific shapes using a mold. This process is particularly ideal for creating plastic thermoformed trays as it provides flexibility in design and production. For example, the trays can be molded with dividers and compartments, offering optimal storage solutions for a variety of applications. The ability to customize the size and shape makes separator trays an invaluable tool for efficient material handling and packaging.

At INPAK, we specialize in producing thermoform machines that are tailored to the production of such trays. Our cutting-edge technology ensures high-quality, precise, and efficient manufacturing of separator trays. These machines not only improve productivity but also provide excellent flexibility in material choices, helping businesses in multiple industries optimize their packaging and logistics processes.

Thermoformed Trays and Boxes

Thermoformed trays and boxes are highly versatile products used across a wide range of industries, including food, electronics, and automotive. The thermoforming process provides the flexibility to create a vast array of shapes and sizes, ensuring that the trays and boxes meet the exact specifications required for the products they are intended to hold. Whether it’s a delicate electronic component or perishable food items, thermoformed plastic trays provide an effective solution for safe and secure storage.

One of the key advantages of thermoformed boxes is their cost-effectiveness. Unlike traditional packaging methods, thermoforming allows for fast production runs with minimal waste. The process is also energy-efficient, making it an environmentally friendly choice. The durable nature of the materials used means that these trays can be reused, offering additional value to businesses that require consistent, reliable packaging solutions. Plastic thermoformed trays also offer excellent protection from physical damage, preventing items from shifting or breaking during transport.

As a manufacturer of thermoforming machines, INPAK provides state-of-the-art equipment designed to produce high-quality thermoformed trays and boxes. Our machines are equipped with advanced features that allow for easy mold changeovers, precise temperature control, and rapid cycle times, ensuring that your production process is both efficient and sustainable. With INPAK’s expertise, companies can rely on robust, customizable, and reliable packaging solutions.

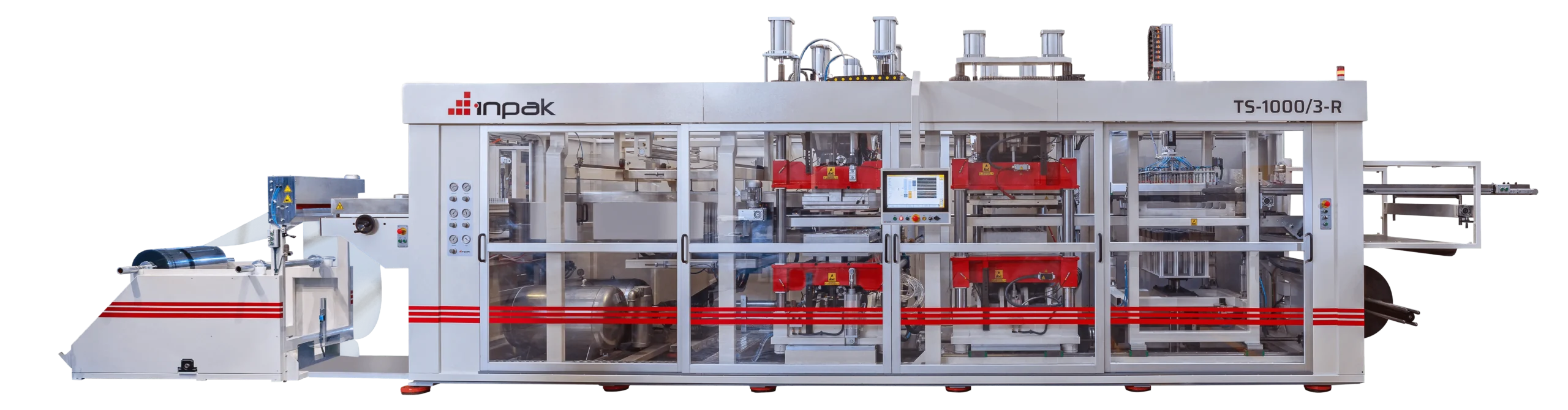

Thermoforming Machines for Tray Production

The heart of any efficient thermoforming tray production process lies in the thermoforming machine. These machines are capable of producing complex and precise shapes by heating a plastic sheet to a moldable temperature, shaping it, and then trimming it to the desired form. Thermoform cornered trays are a popular choice in industries that require specialized packaging solutions, such as the food and electronics sectors. The ability to create custom designs and shapes makes thermoforming machines an essential tool for producing plastic thermoformed trays that meet diverse operational needs.

INPAK’s thermoforming machines are designed for maximum precision and speed, allowing manufacturers to produce large quantities of thermoformed trays and boxes without compromising quality. Our machines support various materials, including PET, PP, and PVC, offering businesses the flexibility to select the ideal material for their specific needs. Whether you need a simple flat tray or a more complex, multi-compartment design, INPAK’s machines can produce thermoformed trays that meet exact specifications every time.

The use of thermoforming machines has revolutionized the production of thermoformed trays and boxes, making them more accessible and cost-effective for businesses of all sizes. At INPAK, we understand the importance of efficiency and reliability in production processes, which is why our thermoforming machines are engineered to reduce downtime, minimize waste, and enhance overall productivity. With INPAK’s equipment, companies can scale their production while maintaining the high standards required for quality packaging solutions.

Applications of Thermoformed Trays

Thermoformed trays are used in a wide range of industries, thanks to their versatility and ability to be customized. In the food industry, these trays are perfect for packaging perishable items, such as fruits, vegetables, meats, and ready-made meals. Thermoformed plastic trays are designed to protect food products, extending their shelf life by providing ventilation and separation. This ensures that the items stay fresh during transportation and storage, which is especially important in the fast-paced food industry.

In the electronics sector, plastic thermoformed trays are used to protect sensitive components during shipment and storage. These trays can be designed with compartments to hold various parts securely, preventing them from being damaged or scratched. Thermoformed separator trays are also widely used in assembly lines, as they allow for easy sorting and transportation of parts, helping streamline the manufacturing process. The customization options of thermoformed trays make them an ideal solution for organizing and protecting delicate items in the electronics industry.

Thermoformed boxes are also crucial in the automotive industry, where they are used to organize and protect parts during manufacturing and transportation. The durability and strength of these trays make them perfect for handling heavy automotive components, while their design allows for easy stacking and storage. INPAK’s thermoforming machines are capable of producing trays and boxes that meet the rigorous standards required by the automotive sector, ensuring that parts are delivered safely and efficiently.

Key Benefits of Using Thermoform Separator Machines in Manufacturing

One of the main advantages of using thermoform separator machines is their ability to enhance productivity in plastic packaging production. By automating the separation process, these machines significantly reduce labor costs and minimize human error. Companies that manufacture thermoforming machines design separator machines to operate at high speeds, ensuring increased output without compromising on quality.

Another key benefit is material optimization. A well-designed plastic packaging machine with an integrated separator ensures minimal material wastage. These machines accurately cut plastic sheets, reducing excess waste and improving overall material efficiency. This is particularly beneficial for companies aiming to reduce their environmental impact and optimize resource utilization.

Precision and consistency are also major advantages of thermoform separator machines. Unlike manual cutting, which may result in inconsistencies, these machines provide uniform and repeatable results. A thermoforming machine manufacturer like Inpak ensures that their separator machines incorporate advanced technologies for precise cutting, resulting in higher-quality finished products.

Step-by-Step Guide to Manufacturing Thermoform Separator Machines

The manufacturing process of thermoform separator machines begins with the design phase. Engineers develop detailed blueprints and 3D models to ensure the machine meets industry standards and customer specifications. The design process includes selecting appropriate materials, determining cutting mechanisms, and optimizing automation features. Companies that manufacture thermoforming machines prioritize innovation to improve the efficiency and functionality of separator machines.

Once the design is finalized, the fabrication phase begins. High-precision CNC machining is used to produce key components such as frames, cutting tools, and control panels. Welding and assembly processes follow, where different parts are securely integrated into a complete plastic packaging machine. During this phase, rigorous quality control measures ensure that each component meets industry standards.

After assembly, the thermoform separator machine undergoes thorough testing. The testing phase involves running the machine under various conditions to evaluate its performance, speed, and accuracy. A thermoforming machine manufacturer like Inpak conducts extensive quality assurance checks before the final installation. Once the machine passes all tests, it is prepared for delivery and installation at the customer’s facility.

Efficient Manufacturing and Installation of Thermoform Machines by Inpak

As a leading thermoforming machine manufacturer, Inpak specializes in the design, manufacturing, and installation of high-performance thermoform machines. The company’s advanced production facilities ensure that each machine meets the highest standards of quality and efficiency. With extensive industry experience, Inpak provides innovative solutions tailored to the needs of plastic packaging manufacturers.

The installation process is just as critical as manufacturing. Inpak ensures that every plastic packaging machine is installed correctly, optimizing its performance and longevity. Expert technicians handle the installation, calibrating machine settings to align with the customer’s production requirements. Proper installation guarantees smooth operation and minimizes the need for frequent maintenance.

Customer support and training are essential aspects of Inpak’s service. The company provides comprehensive training for machine operators, ensuring they understand the functionalities and maintenance procedures. By offering end-to-end solutions, Inpak helps businesses achieve maximum efficiency in their thermoforming operations. Companies that manufacture thermoforming machines must not only focus on production but also on providing seamless installation and long-term support, making Inpak a trusted partner in the industry.