The Importance of Thermoforming Technology in Food Packaging

What is the importance of thermoforming technology in food packaging? Thermoforming technology plays a crucial role in the food packaging industry by enabling the production of lightweight, durable, and cost-effective packaging solutions. The process involves heating a plastic sheet until it becomes pliable, then forming it into a specific shape using molds. This technology is ideal for creating containers, trays, and other packaging types that protect and preserve food products efficiently. The versatility of thermoforming machines makes them indispensable in high-volume food packaging production, allowing companies to customize packaging according to the needs of different food products.

Table of Contents

The adoption of thermoforming technology has also helped enhance sustainability in food packaging. Manufacturers are now able to create packaging using thinner plastics, reducing material waste and contributing to a greener environment. This is particularly important in a market where the protection and preservation of food are paramount. Thermoforming provides a reliable solution to safeguard food from contamination by external elements, ensuring longer shelf life and improved product quality.

In addition, thermoforming technology has revolutionized the design of food packaging. It allows for the production of customized shapes and sizes that cater to the unique requirements of various food products. This flexibility has contributed to the widespread use of thermoforming in packaging different types of food, from fresh produce to ready-to-eat meals, enhancing both the functionality and aesthetics of food packaging. What is the importance of thermoforming technology in food packaging?

The Impact of Thermoforming on the Food Industry

Thermoforming has had a transformative impact on the food industry by streamlining production processes, reducing packaging costs, and offering new packaging designs. The ability to form intricate shapes with thermoforming machines is especially valuable in the food sector, where packaging not only serves a protective function but also plays a role in product marketing and consumer appeal. With the growing demand for convenience food, thermoforming has enabled the production of portion-controlled, easy-to-handle packaging that meets consumer needs for on-the-go meals and snacks.

Moreover, thermoforming technology has led to the rise of more sustainable packaging solutions. In the past, many food products were packaged using materials that were not environmentally friendly. Today, thermoformed packaging made from recyclable materials is gaining popularity as consumers and manufacturers alike become more eco-conscious. The use of thermoforming in the food industry aligns with the global trend toward more sustainable packaging options, ensuring that food companies meet both regulatory requirements and consumer preferences.

Thermoforming also plays a vital role in reducing food waste. By providing precise packaging that fits the food product perfectly, thermoforming minimizes the use of excess material while offering better protection. This results in less waste and contributes to the preservation of food, ensuring that products stay fresh longer and reach consumers in optimal condition.

How Thermoforming is Transforming the Food Industry

Thermoforming is changing the food packaging landscape by making packaging solutions more efficient, cost-effective, and customizable. The speed and efficiency of the thermoforming process allow manufacturers to meet the growing demand for packaged foods while keeping production costs low. This technology has also enabled the creation of packaging that is not only functional but also visually appealing, enhancing the overall consumer experience. From single-serve portions to multi-compartment containers, thermoforming offers a wide range of packaging solutions for the food industry.

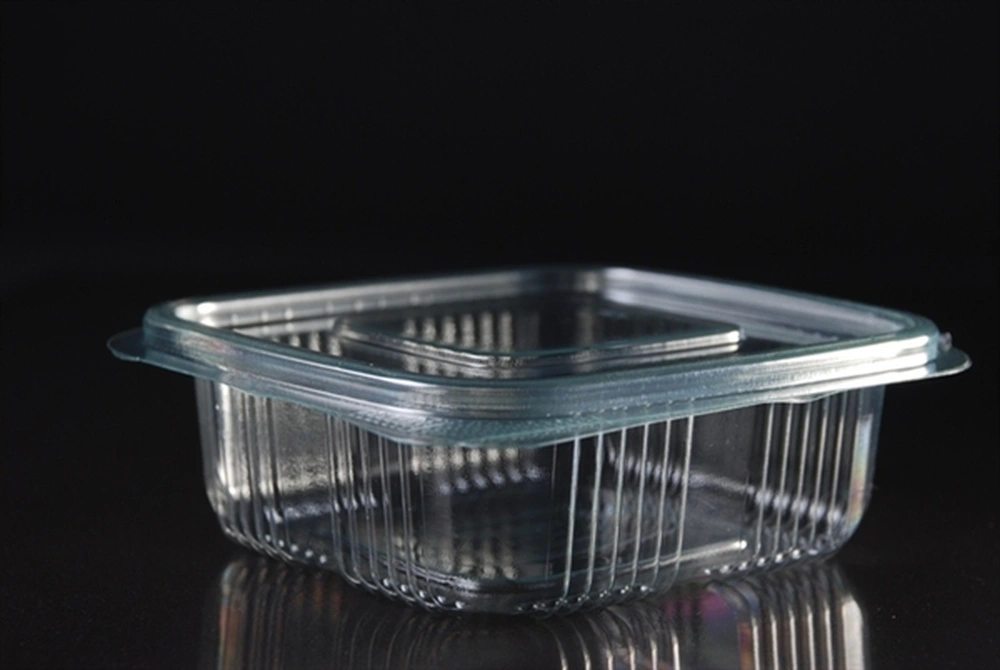

Additionally, thermoforming has contributed to the development of packaging that provides greater convenience for consumers. Features like easy-open lids, resealable packages, and clear containers improve the usability of food packaging. This flexibility in design allows manufacturers to cater to specific consumer needs, whether it’s for fresh produce, frozen foods, or ready-to-eat meals. Thermoforming technology also supports the demand for transparent packaging, allowing consumers to see the product inside and making it easier to assess its quality.

The impact of thermoforming on food preservation is also significant. Packaging created through thermoforming provides an airtight seal that protects food from exposure to air, moisture, and contaminants. This ensures longer shelf life and maintains the freshness of perishable items, such as dairy, meats, and fruits. As a result, thermoformed packaging not only meets the functional needs of food manufacturers but also contributes to the overall sustainability of the food industry.

Common Materials Used in Thermoforming for the Food Industry

Thermoformed food packaging is typically made from several types of plastic materials, each chosen for their ability to form easily, provide durability, and offer protection to the food product. Some of the most common materials used in thermoforming include polystyrene (PS), polyethylene terephthalate (PET), polypropylene (PP), and polyvinyl chloride (PVC). These materials are selected based on their ability to withstand the heat during the thermoforming process and their suitability for different types of food packaging.

PET is one of the most commonly used materials in thermoforming due to its strength, clarity, and recyclability. It is particularly ideal for packaging perishable food products, such as fruits, vegetables, and meats. Additionally, PET’s lightweight nature helps reduce transportation costs, making it a cost-effective choice for manufacturers. Polypropylene (PP) is another widely used material because of its resistance to heat, moisture, and chemicals, making it suitable for packaging hot or frozen foods.

As sustainability becomes more important in the food packaging industry, the use of recyclable materials has become a key trend. Thermoforming machines are now capable of working with these eco-friendly materials, providing food manufacturers with the ability to produce packaging that is both functional and sustainable. The growing consumer demand for environmentally friendly packaging solutions has pushed the industry toward more innovative, sustainable packaging options.

Benefits of Thermoformed Packaging in the Food Industry

Thermoformed packaging offers numerous benefits to the food industry. One of the primary advantages is its cost-effectiveness. The speed and efficiency of the thermoforming process make it a suitable option for large-scale production, helping food manufacturers meet the high demand for packaged products while keeping costs down. Furthermore, the versatility of thermoforming allows for the creation of custom packaging solutions tailored to the specific needs of different food products.

Another significant benefit is the superior protection thermoformed packaging offers. The airtight seals created during the thermoforming process prevent air, moisture, and contaminants from affecting the food. This ensures longer shelf life, reduces spoilage, and helps maintain the quality of the food until it reaches the consumer. This level of protection makes thermoforming ideal for packaging a wide range of food products, from fresh items to frozen and ready-to-eat meals.

Thermoforming also contributes to consumer convenience. With packaging that is easy to handle, store, and open, thermoformed containers improve the overall user experience. Additionally, features like resealable lids and portion-controlled packaging cater to modern consumer preferences for convenience and portioning. This has made thermoformed packaging the preferred choice for many food companies looking to meet the needs of today’s busy consumers.

Why Are Thermoforming Machines Important in Food Packaging?

What is the importance of thermoforming technology in food packaging? Thermoforming machines are essential in the food packaging industry because they enable manufacturers to produce high-quality, cost-effective packaging solutions at scale. These machines provide the precision and flexibility needed to create packaging that meets the specific requirements of different food products, from portion sizes to shape and material specifications. As demand for packaged food continues to grow, the role of thermoforming machines becomes even more critical in helping companies produce packaging that is both efficient and protective.

The importance of thermoforming machines extends beyond cost savings and efficiency. These machines allow food manufacturers to use recyclable and sustainable materials, contributing to a more eco-friendly packaging solution. With increasing consumer demand for sustainable products, thermoforming machines are playing a key role in the development of packaging that minimizes environmental impact while meeting the needs of food manufacturers and consumers.

Thermoforming machines also enhance the speed and efficiency of the packaging process. With the ability to produce large volumes of packaging quickly, these machines help reduce production time and costs. As food packaging continues to evolve, thermoforming machines will remain an integral part of the industry, providing high-quality, customizable packaging solutions that ensure food safety, sustainability, and consumer satisfaction.

The Importance of Thermoforming Technology in Food Packaging

INPAK Thermoforming Machine Supply

INPAK is a leading supplier of thermoforming machines, offering high-performance solutions designed to meet the needs of the food packaging industry. With advanced technology and a focus on sustainability, INPAK provides manufacturers with machines capable of producing packaging that is both functional and eco-friendly. Their commitment to innovation ensures that food companies can rely on their thermoforming machines to deliver high-quality packaging that protects food products and extends their shelf life.

By offering versatile and efficient thermoforming machines, INPAK helps food manufacturers streamline their production processes and meet the growing demand for packaged goods. As the food packaging industry moves toward more sustainable solutions, INPAK remains at the forefront, offering cutting-edge technology that meets the evolving needs of food manufacturers and consumers alike. Their advanced thermoforming machines are key to shaping the future of food packaging, ensuring that manufacturers can produce high-quality, eco-friendly packaging at scale.