Thermoforming Machines Offering High Profitability (ROI)

In the manufacturing industry, thermoforming machines offering high profitability (ROI) are highly regarded for their ability to produce high-quality plastic products efficiently. These machines are designed to mold plastic sheets into different shapes using heat and pressure, making them ideal for various applications, from packaging to medical products. As industries continue to demand more customized and cost-effective solutions, thermoforming machines offer a significant return on investment by enabling high-volume production with reduced material wastage. Their versatility in producing a wide range of products makes them an attractive option for companies looking to boost profitability.

Table of Contents

By investing in advanced thermoforming technology, companies can achieve a higher ROI through improved operational efficiency. Thermoforming machines are engineered to work at high speeds, which reduces cycle times and increases output. This leads to greater productivity, meaning manufacturers can meet higher demand levels with minimal downtime. Additionally, modern machines often come with automated features that reduce human intervention, enhancing consistency and minimizing the risk of errors, further contributing to long-term profitability.

Moreover, the durability and reliability of Thermoforming machines ensure that manufacturers can sustain high levels of production over extended periods. While the initial investment in high-end machines might be substantial, the ongoing savings in maintenance costs, energy consumption, and raw material usage translate into a significant return on investment. Manufacturers who invest in these machines can enjoy long-term benefits, including a high profit margin and a competitive edge in the market.

What is ROI?

Return on Investment (ROI) is a financial metric that businesses use to evaluate the profitability of an investment. It is a straightforward way to determine how effectively a company is using its capital to generate profits. The ROI formula is calculated by dividing the net profit from an investment by the initial cost of the investment, and then multiplying by 100 to express the result as a percentage. A higher ROI indicates that the investment has generated significant returns relative to its cost, which is an essential indicator of business efficiency and growth potential.

In the context of thermoforming machines, ROI can help manufacturers understand the long-term value of their equipment. It provides a clear picture of whether the machine’s capabilities align with the production goals and financial targets of the business. For example, if a company invests in a new thermoforming machine and sees an increase in production rates and a decrease in material waste, it can calculate the ROI to determine the overall effectiveness of the purchase. By focusing on ROI, manufacturers can make data-driven decisions about future investments in machinery and technology.

Moreover, ROI is essential in comparing different types of investments. For instance, if a company is considering upgrading its existing thermoforming equipment, calculating the ROI of the new machine compared to the older model can help make an informed decision. By doing so, businesses can choose the most cost-effective solution that provides the highest potential for profitability.

What Should the ROI Value Be?

The ideal ROI value can vary depending on the industry, the scale of the business, and the specific objectives of the investment. Generally, businesses aim for an ROI that significantly exceeds the cost of the investment. A common benchmark for a good ROI is around 20-30%, meaning that for every dollar invested, the company should expect to generate $1.20 to $1.30 in return. However, a higher ROI is always desirable, as it indicates that the business is optimizing its resources and maximizing profitability.

For Thermoforming machines, a strong ROI typically reflects both tangible and intangible benefits. A positive ROI can be achieved not only through increased output and reduced production costs but also through improved product quality and market competitiveness. Manufacturers should also consider the lifespan of the machine, as a higher ROI over a longer period will often outweigh the initial cost of purchase. Additionally, industries with tighter profit margins may expect a higher ROI value to ensure the equipment delivers enough financial return to justify the investment.

That said, ROI expectations should be realistic and aligned with the company’s goals. Some businesses may have a lower ROI threshold, particularly in industries where the upfront cost of machinery is high, but the long-term value is considerable. By setting a target ROI value, manufacturers can assess whether their investment in thermoforming machines aligns with their financial and operational objectives, ensuring they get the most out of their purchase.

Ways to Increase Efficiency in Production with Thermoforming Machines

Increasing efficiency with thermoforming machines involves optimizing various aspects of the production process, from material selection to machine settings. One way to achieve higher efficiency is through the use of advanced automation systems. These systems allow for faster and more precise production by reducing human error and minimizing downtime between cycles. Additionally, incorporating real-time monitoring and feedback systems can help identify potential bottlenecks in production, enabling operators to make quick adjustments for optimal performance.

Another strategy for increasing efficiency is the use of high-quality, cost-effective materials. By selecting the right type of plastic and optimizing the thermoforming process to minimize waste, manufacturers can significantly reduce material costs. In addition, advanced thermoforming machines come equipped with energy-efficient technologies that help minimize electricity consumption during production. Over time, these savings in energy and materials can significantly improve overall efficiency and profitability.

Furthermore, investing in employee training and maintenance programs can contribute to higher efficiency levels. Well-trained staff can operate machines more effectively and identify potential issues before they become major problems. Regular maintenance ensures that the machines are always in top working condition, reducing the risk of unexpected breakdowns and increasing uptime. By combining these efforts, manufacturers can streamline their production process and significantly increase the efficiency of their thermoforming machines.

Reducing Costs and Increasing Profitability with a Thermoforming Machine

Thermoforming machines play a pivotal role in reducing production costs and increasing profitability. By automating much of the manufacturing process, these machines reduce the need for manual labor, leading to lower labor costs. Additionally, modern thermoforming machines are designed to operate at high speeds, reducing cycle times and increasing output. This increased throughput allows manufacturers to produce more units in less time, which directly contributes to higher revenue and profitability.

In terms of material costs, thermoforming machines are highly efficient, as they can be programmed to optimize material usage. This reduces waste and ensures that the plastic sheets are molded with precision, leading to fewer defective products. The ability to produce consistent, high-quality products also reduces the number of returns and rework, which can eat into profits. By enhancing product quality and reducing scrap, manufacturers can achieve a more cost-effective production process.

Thermoforming machines can also help manufacturers scale their operations without the need for significant investments in additional resources. As demand increases, businesses can rely on the increased capacity of the machines to meet production goals without needing to hire more workers or invest in new facilities. This scalability, combined with reduced material waste and labor costs, helps businesses maintain a competitive edge while maximizing profitability.

Low Labor Costs and High ROI with INPAK Thermoforming Machines

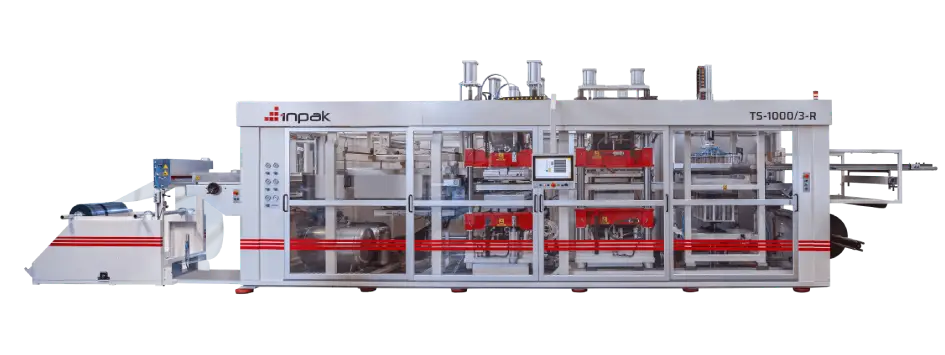

INPAK thermoforming machines are designed to deliver high ROI through their efficiency, reliability, and automation. One of the primary ways these machines achieve high ROI is by significantly reducing labor costs. With automated features, INPAK machines can operate with minimal human intervention, reducing the number of employees needed on the production floor. This allows businesses to allocate resources more effectively and reduce overall labor expenses.

The advanced automation and user-friendly design of INPAK thermoforming machines also contribute to higher efficiency. Operators can quickly learn to operate these machines, reducing training time and ensuring that production runs smoothly. With fewer interruptions and faster setup times, companies can boost productivity and meet customer demands more effectively. As a result, INPAK machines provide businesses with a reliable solution for maintaining high production rates and profitability.

Additionally, INPAK’s commitment to quality and durability ensures that these machines require minimal maintenance, further contributing to cost savings. With fewer breakdowns and extended service life, businesses can maximize the value of their investment. By offering both operational efficiency and low maintenance costs, INPAK thermoforming machines provide a clear pathway to high ROI and long-term profitability.