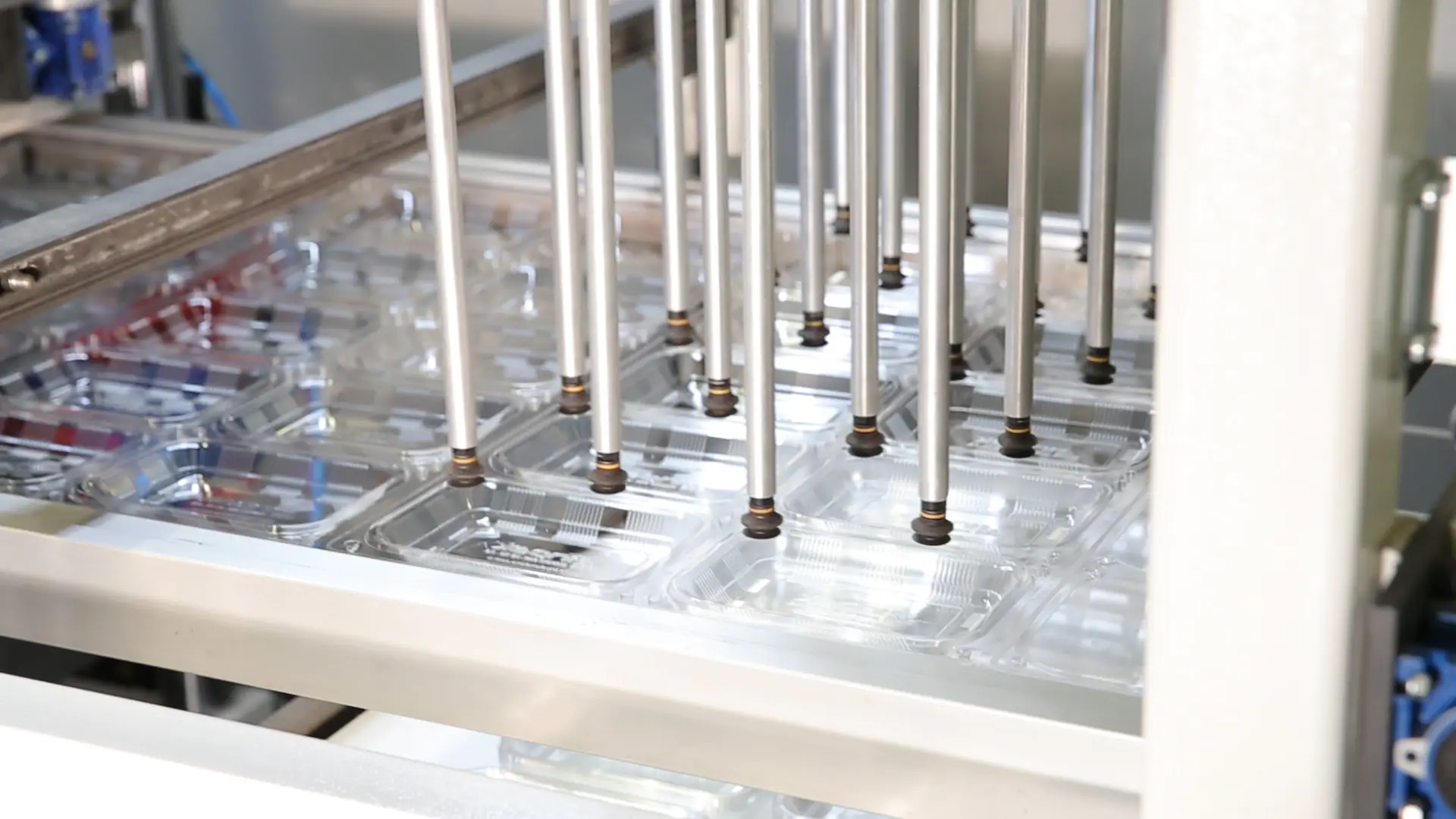

TS-800 Thermoforming Machine: A Game-Changer in Thermoforming Packaging

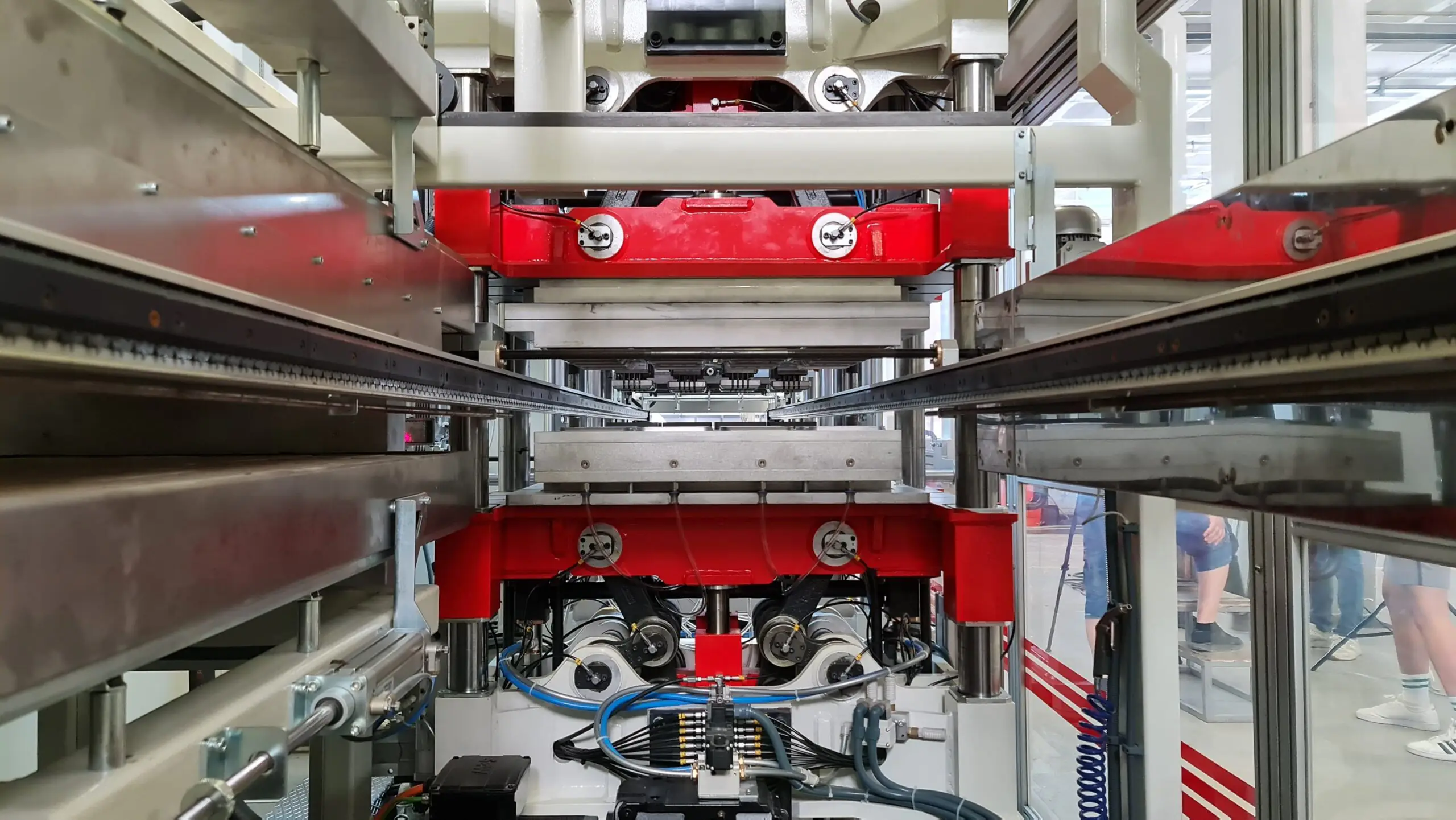

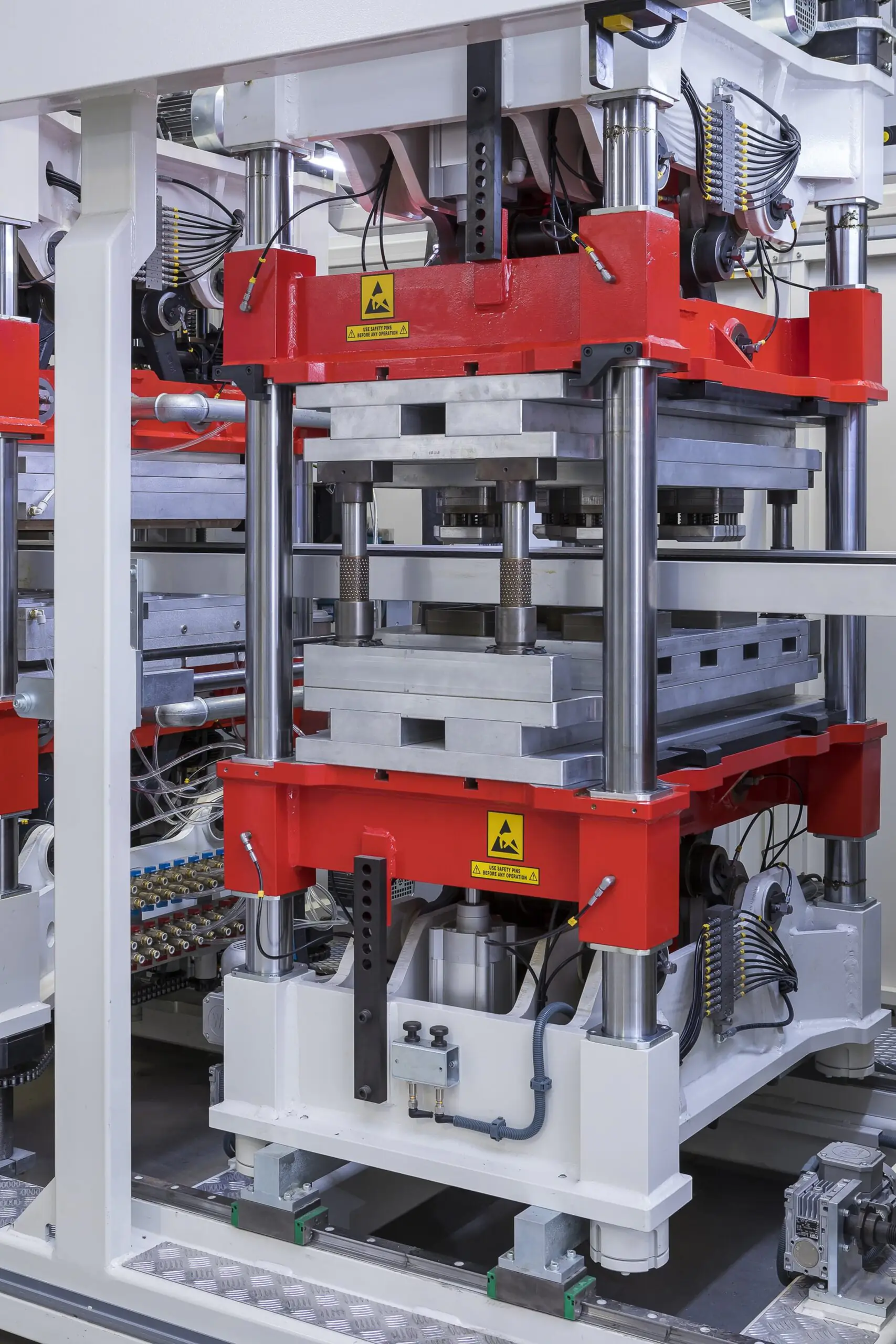

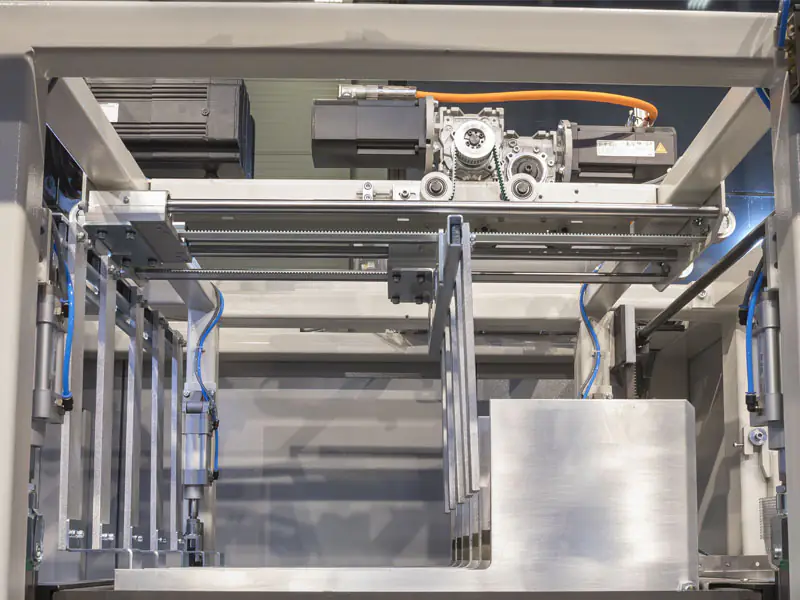

The TS-800 Thermoforming Machine by INPAK is specifically designed for businesses in the plastic packaging industry that demand high performance and reliability. This advanced thermoforming machine seamlessly integrates cutting-edge technology with practical features, making it the go-to choice for manufacturers seeking efficiency, speed, and precision in their production processes.

Superior Specifications for High-Quality Production

The TS-800 Thermoforming Machine boasts impressive specifications tailored to meet the needs of modern manufacturing:

- Maximum Mold Dimensions: 800 x 580 mm, providing exceptional flexibility for a variety of thermoforming packaging applications.

- Maximum Sheet Width: 840 mm, allowing the use of larger thermoforming plastic sheets for versatile production requirements.

- Cycle Speed: Up to 75 dry cycles per minute, ensuring fast, reliable, and consistent output under demanding conditions.

This high-performance thermoforming machine supports a wide range of materials, including PET, CPET, PP, PVC, PS, OPS, and PLA, with a maximum sheet thickness of 1.5 mm. Whether you’re creating thermoform packaging for food, medical supplies, or other consumer goods, the TS-800 is built to deliver exceptional durability and precision.

Energy Efficiency and Robust Power

Energy efficiency is a cornerstone of the TS-800 Thermoforming Machine’s design:

- Power Consumption: 25–50 kW, ensuring cost-effective, long-term operation.

- Total Installed Power: 130–170 kW, offering robust performance for high-demand production.

- Vacuum Pump Capacity: 100 m³/hour, enhancing the precision and reliability of vacuum forming machineprocesses.

The TS-800 is engineered to deliver consistent results while minimizing energy costs, making it an environmentally friendly and economical solution for manufacturers.

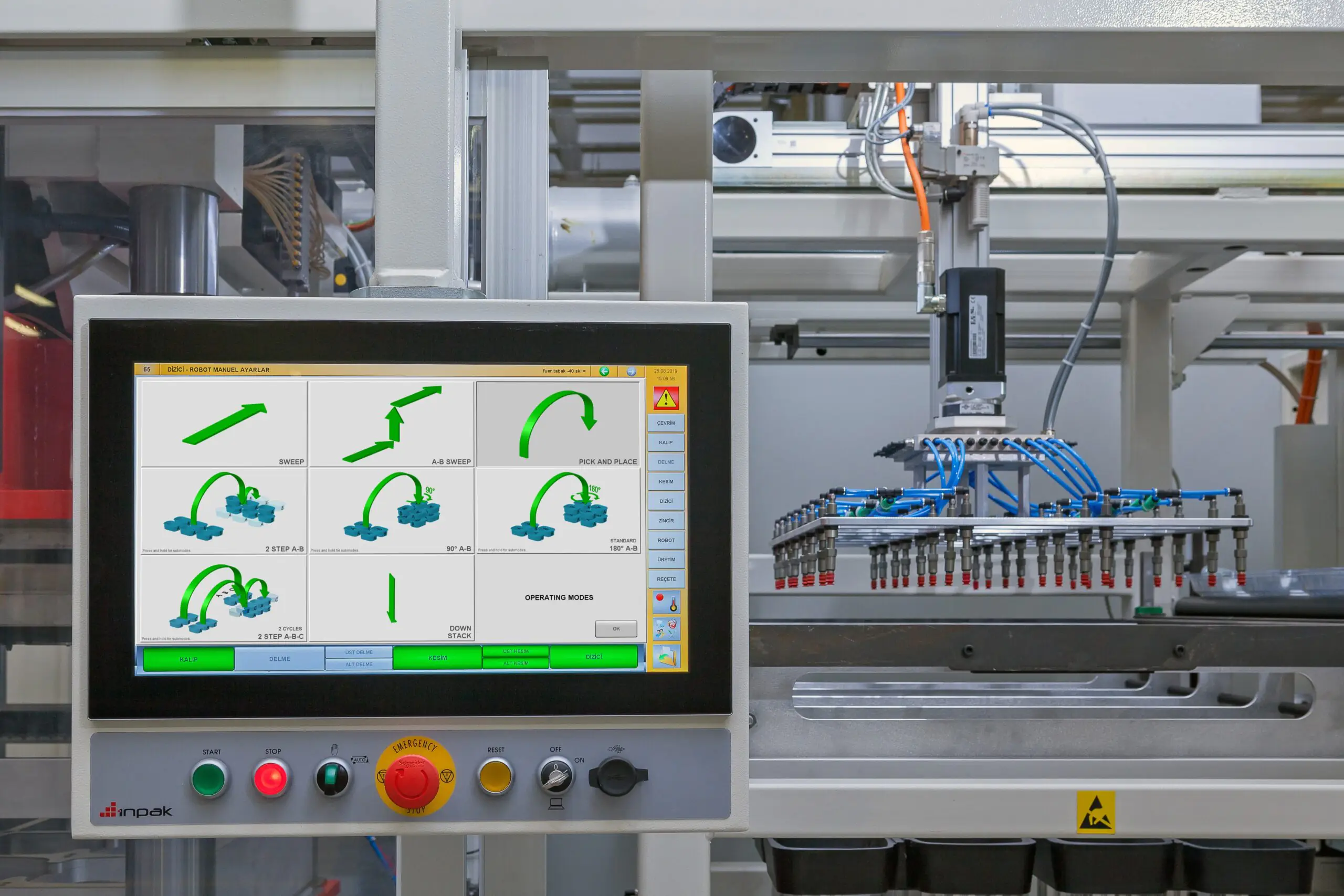

Intuitive Control and User Experience

Equipped with advanced automation and user-friendly features, the TS-800 Thermoforming Machine offers seamless operation:

- Control Unit: Powered by a B&R Industrial PC for precise control and automation.

- Touch Screen: Features an 18.5-inch B&R Colorful Touchscreen for intuitive operation and real-time monitoring.

- Central Lubrication System: Integrated with PC-controlled BEKA-MAX software for reduced maintenance and extended lifespan.

These features ensure that the thermoforming machine is easy to operate, even for high-volume production settings.

INPAK: A Trusted Name in Thermoforming Machine Manufacturing

As a globally recognized thermoforming machine manufacturer, INPAK has established a reputation for delivering reliable, energy-efficient, and innovative solutions tailored to the unique needs of the plastic packaging industry. By combining sustainability, advanced technology, and user-friendly designs, INPAK continues to lead the way in thermoforming machine innovation.

Revolutionizing Plastic Packaging with the TS-800 Thermoforming Machine

The TS-800 Thermoforming Machine is more than just a piece of equipment—it’s a comprehensive solution for businesses looking to elevate their production capabilities. With advanced features and unmatched reliability, the TS-800 is the ideal choice for manufacturers aiming to remain competitive in today’s dynamic market.

If you’re searching for a trusted partner in thermoforming machine technology, look no further than INPAK. The TS-800 exemplifies our commitment to quality and innovation in the fields of thermoforming packaging and vacuum forming technology. Contact us today to learn how the TS-800 can transform your production processes.