What Are The Materials Used In Thermoforming Machines?

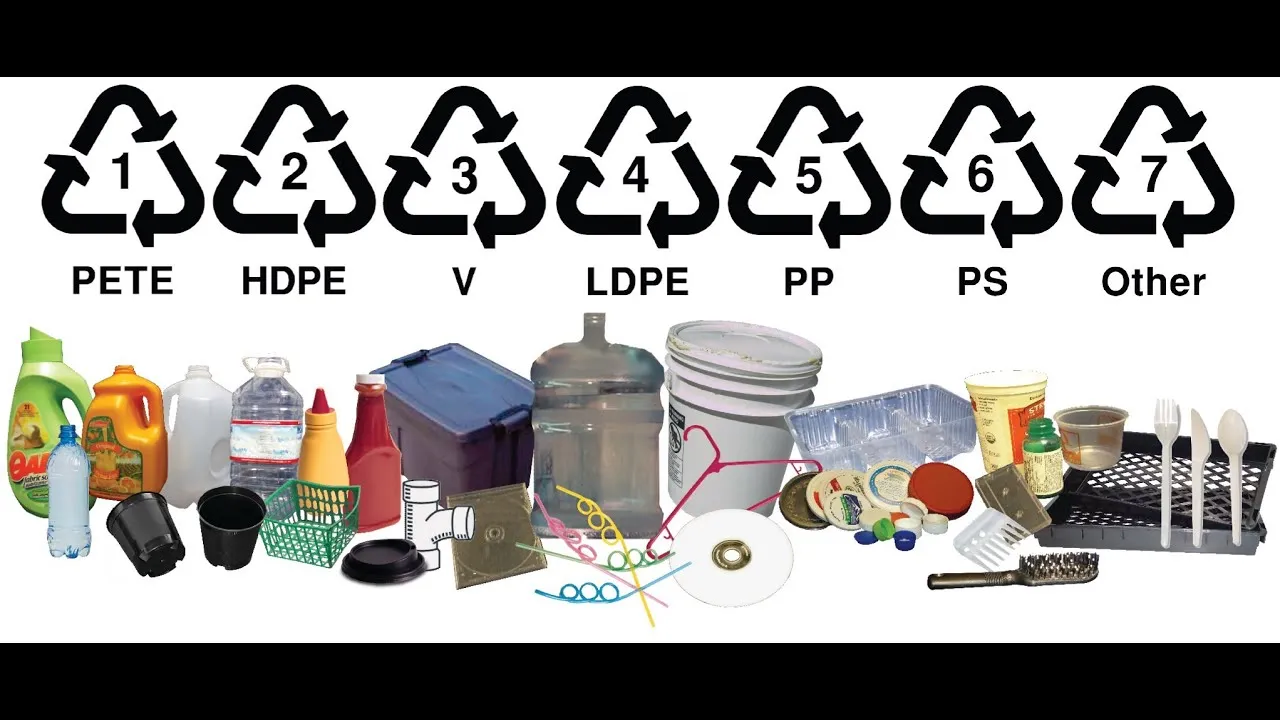

What are the materials used in thermoforming machines? Thermoforming is a manufacturing process used to create plastic products by heating a sheet of plastic until it becomes pliable and then molding it into a desired shape. The materials used in thermoforming machines vary depending on the specific application, but they must be suitable for high temperatures and flexible enough to form into intricate shapes. These materials include a wide range of thermoplastics that can withstand heat and pressure, and are widely used in packaging, automotive, medical, and other industries. Popular plastics include polystyrene, polyethylene, and polypropylene, which are known for their ability to be molded easily when heated and retain their shape once cooled.

Table of Contents

The choice of material depends on the intended use of the product. For example, in the plastic packaging machine industry, materials like polyethylene (PE) and polyvinyl chloride (PVC) are common due to their strength and cost-effectiveness. These materials are ideal for producing a variety of food containers and other packaging products that require a balance of rigidity and flexibility. In more specialized applications such as medical packaging, materials like polycarbonate are favored for their clarity and high impact resistance, while Acrylic (PMMA) is used for applications requiring transparency and UV resistance.

Furthermore, environmental considerations are becoming increasingly important, and the use of recycled plastics is on the rise. Recycled polyethylene terephthalate (PET) is gaining popularity as a thermoforming material because it offers good formability and can be recycled multiple times, contributing to sustainability. Manufacturers of thermoforming machines like Inpak are incorporating designs that allow for the use of recycled materials, ensuring that their products contribute to reducing waste in the packaging industry. What are the materials used in thermoforming machines?

What is the most common thermoforming material?

The most common material used in thermoforming is polystyrene (PS). This material is widely preferred due to its ease of use, versatility, and cost-effectiveness. Polystyrene is commonly used in applications such as disposable food containers, blister packs, and trays. It is easy to form, and once cooled, it provides a solid, rigid finish, making it ideal for products that need to maintain their shape and provide a protective layer for the items inside.

Another widely used thermoforming material is polyethylene (PE), which is chosen for its flexibility, toughness, and resistance to impact. It is used in a variety of applications, including food packaging, plastic bags, and shrink wraps. Polypropylene (PP) is also common, offering higher heat resistance than polyethylene, which makes it suitable for packaging hot food items. Polypropylene is often used for containers, trays, and clamshell packages in the food industry, where heat resistance and clarity are important.

Each of these materials is highly adaptable to different thermoforming processes, allowing for the production of a wide range of products. The choice of material depends on factors like the required durability, flexibility, clarity, and environmental impact. Thermoforming machine manufacturers, such as Inpak, carefully select the most suitable material for each application, ensuring that the products meet the necessary performance and sustainability standards.

What material is used for thermoforming?

In thermoforming, the material is typically a plastic sheet or film that is heated to a temperature where it becomes pliable enough to be shaped by pressure or vacuum. The most common materials used include polystyrene (PS), polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC). These materials are chosen based on their ability to be molded under heat and pressure, and their ability to maintain their shape once cooled.

Polyethylene and polypropylene are frequently used in food packaging applications due to their strength, durability, and resistance to moisture and chemicals. These materials are also more cost-effective compared to others, making them ideal for mass-produced items like food trays, containers, and lids. Polyvinyl chloride (PVC), though not as commonly used as polyethylene, is still a popular choice in industries requiring high impact resistance and a glossy finish, such as in the creation of medical trays or retail packaging.

Additionally, the use of recycled materials is becoming more prevalent in the thermoforming process. Plastics like recycled PET (Polyethylene Terephthalate) and recycled HDPE (High-Density Polyethylene) are used as eco-friendly alternatives, reducing the environmental footprint of thermoformed products. Manufacturers of plastic packaging machines like Inpak are adopting these materials to meet the growing demand for sustainable packaging solutions.

What is the best material for thermoforming molds?

The best material for thermoforming molds depends on several factors, including the type of product being produced, the level of detail required, and the durability of the mold. Materials commonly used for thermoforming molds include aluminum, steel, and brass, each offering distinct advantages. Aluminum is often chosen for its light weight, ease of machining, and ability to be quickly manufactured. It is suitable for short-run production or low-volume applications where speed and cost-efficiency are important considerations.

For higher-volume production, steel is typically preferred due to its strength and durability. Steel molds can withstand the high temperatures and pressures involved in the thermoforming process without deforming, making them ideal for mass production. Brass is another option, often used for its good thermal conductivity and ability to resist corrosion, making it a suitable material for molds that will be exposed to high temperatures repeatedly.

The choice of mold material is important because it affects the overall quality and longevity of the product being formed. Manufacturers like Inpak ensure that their thermoforming machines are equipped to handle various mold materials, providing customers with the flexibility to choose the best solution for their production needs.

Common Plastics Used in Thermoforming

Several types of plastics are commonly used in thermoforming processes, each offering unique characteristics that make them suitable for different applications. Polystyrene (PS), one of the most widely used plastics, is favored for its affordability and ease of use. It is used for a variety of products, including food packaging, cups, and containers. Polyethylene (PE) is another popular material, known for its flexibility and durability, making it ideal for packaging, shrink wraps, and even medical devices.

Polypropylene (PP), which offers higher heat resistance than polyethylene, is often used in applications that involve exposure to higher temperatures, such as food containers and trays. For more specialized uses, polycarbonate (PC) and Acrylic (PMMA) are chosen for their clarity, strength, and UV resistance. PVC is also a versatile material, used for packaging, signage, and various consumer goods, though it has fallen out of favor in some applications due to environmental concerns.

Factors to Consider When Purchasing a Thermoforming Machine

When purchasing a thermoforming machine, there are several factors to consider. The first is the material compatibility of the machine. It is crucial to ensure that the machine can handle the types of plastics required for the intended production. Additionally, the machine’s production capacity and efficiency are important factors to evaluate. A machine that can produce high volumes of products with minimal downtime will be a more cost-effective investment in the long term.

Another important consideration is the level of automation the machine offers. Automated thermoforming machines reduce the need for manual labor and increase production speed, making them ideal for high-volume manufacturing. The ease of maintenance and availability of spare parts should also be taken into account. Machines that are easy to maintain and have a reliable support network ensure smoother operations.

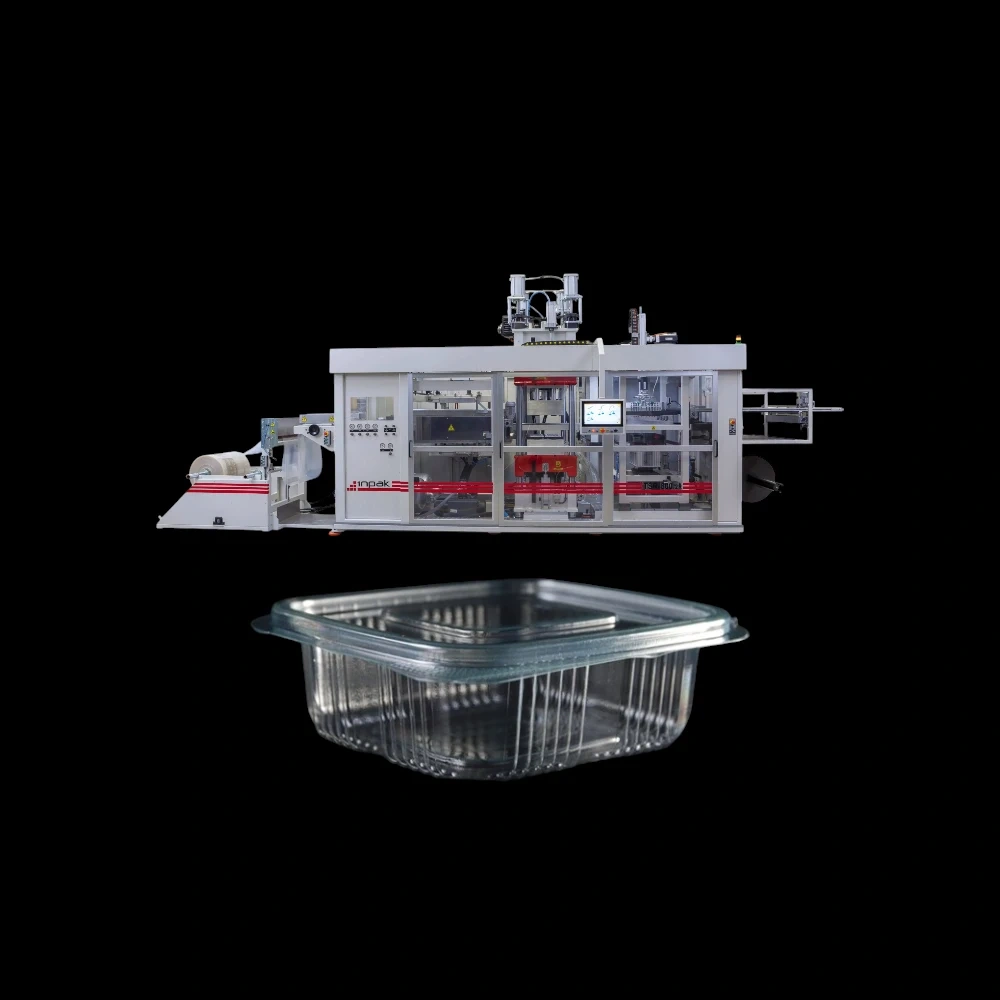

Inpak, a leader in the thermoforming machine production industry, offers high-quality machines designed to meet the demands of various industries. Their machines are engineered for efficiency, durability, and versatility, allowing manufacturers to produce high-quality thermoformed products in a cost-effective manner.

INPAK: A Leading Company in Thermoforming Machine Production

Inpak has established itself as a trusted name in the thermoforming machine production sector. With years of experience and a commitment to innovation, Inpak provides advanced thermoforming solutions that cater to a wide range of industries, from food packaging to medical devices. Their machines are known for their precision, durability, and ability to process various types of thermoplastics.

Inpak’s focus on sustainability is evident in their use of eco-friendly materials and the development of energy-efficient machines. As the demand for sustainable packaging grows, Inpak continues to lead the way in providing solutions that reduce environmental impact while meeting the high standards of quality and efficiency required by manufacturers. Their expertise in plastic packaging machines ensures that their clients receive top-of-the-line equipment tailored to their specific production needs.